Extruded activated carbon

Extruded activated carbon columnar is a porous adsorbent material, which is made by crushing carbon into powder, mixing it with other binders, grinding it into granules on a continuous extruder, and then activating it at high temperature. The raw materials of columnar activated carbon mainly include anthracite, coconut shell, wood chips and so on.

Columnar activated carbon has a wide range of applications, it can be used as an adsorbent for the purification of toxic gases, waste gas treatment, purification and treatment of industrial and domestic water, solvent recovery and so on.

Product Features:

- High mechanical strength

- Good adsorption performance

- Suitable for gas phase adsorption

- Diameter Size: 0.9mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, others

- Packaging: 25kg/bag, 500kg/bag, customized bags

- Delivery time 5-20 days (consult our business for customized solutions)

We can do beyond your imagination

As a professional manufacturer specializing in extruded activated carbon production, we take pride in delivering a variety of high-quality columnar activated carbon products. With advanced production processes and outstanding technical expertise, we are not only capable of meeting the diverse needs of various industries but also providing a wide range of choices for our customers.

1. Sources of raw materials

Produced from locally sourced Taixi coal, but also from high quality coconut shells or wood.2. Diameter Size Parameters

0.9mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, others3. CTC value (%)

20-120, commonly 50, 60, 70, 80.4. Impregnation type

- KI impregnated

- KOH impregnated

- NaOH impregnated

- Copper impregnation

- Sulfur impregnated for mercury removal

- Mercury impregnated for desulfurization

The Manufacturing Process of Small Diggers

Raw material preparation process

We select local high quality anthracite coal (low sulfur, low ash), which is crushed, screened or pulverized and prepared into raw coal with qualified particle size. We also choose high quality coconut shell or fruit shell as raw material.

Kneading and molding process

Qualified coal powder is mixed with a fixed amount of binder and additives at a certain temperature to form a uniform paste. The mixed paste is extruded under a certain pressure to make raw charcoal strips of a certain diameter, called molding. The molding equipment we use is a four-column hydraulic press.

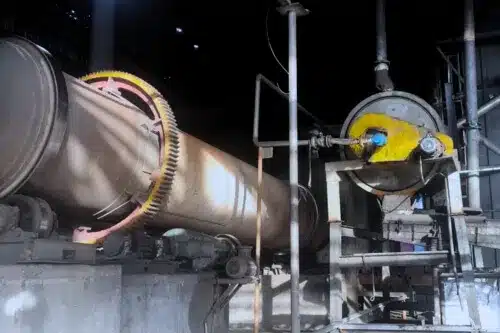

Carbonization and activation processes

After drying the extruded carbon strips, they are carbonized at a high temperature under air-isolated conditions to produce carbon-based materials. After that, activation treatment is carried out to increase the pore structure and specific surface area of the material by means of physical activation, so as to improve its adsorption performance.

Pickling, dipping, drying (optional on request)

Pickling and impregnation are common additional steps in the process of activated carbon production to meet specific needs and improve the performance of the activated carbon.

Acid washing aims to improve the purity and adsorption properties of the activated carbon and also adjusts the pH value of the product.

The impregnation process customizes the properties of the activated carbon by immersing it in a solution containing specific substances. This process adjusts and improves the chemical properties of the activated carbon to suit different application scenarios.

When performing these processes, we follow relevant safety standards and production norms to ensure the quality and performance of the final product.

Sieving, packaging, quality control

In the final stage of activated carbon production, key steps include sieving, packaging and quality control. First, the sieving process ensures that the product meets the specified particle size criteria. This helps to improve the uniformity and effectiveness of the activated carbon in the application.

The quality control process is an important part of ensuring that the product meets standards and specifications. By performing quality tests, assays, and possible third-party certifications, it is ensured that the performance indicators of the activated carbon meet the expected standards. This includes testing of parameters such as CTC, specific surface area, strength, etc. to ensure the stability and reliability of the final product.

Get in touch with us today

Extruded activated carbon pellet applications

Columnar activated carbon is a high quality industrial adsorbent material with a wide range of applications. In air purification, water treatment, industrial waste gas reduction and solvent recovery, columnar activated carbon plays an excellent adsorption, separation and purification function.

- Gas treatment

- Sewage Treatment

- H2S Removal

- Vapor Recovery

- Mercury Removal

- Desulfurization and Denitrification

- Vapor Recovery

- Solvent Recovery

- Gasoline Vapor Capture

- Catalyst Carriers

- Gold Recovery

Purchase activated carbon from true manufacturers

Welcome to choose us, your trusted manufacturer. We have a range of unique advantages to ensure you get the best products and services during the cooperation process.

- Strong technical strength

- 100% quality assurance

- Adequate product inventory

- Advantageous price

- Fast delivery

- Flexible customized service

Request A Free Quote

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours.