In industrial production, solvents are widely used, but their volatilization can lead to resource waste and environmental pollution. Solvent recovery, which involves reclaiming volatilized organic solvents for reuse, has become an important method for reducing pollution and saving resources.

Activated carbon, with its excellent adsorption properties, has become an ideal material in the field of solvent recovery.

This article will focus on the application and advantages of activated carbon in solvent recovery.

Working Principle Of Activated Carbon In Solvent Recovery

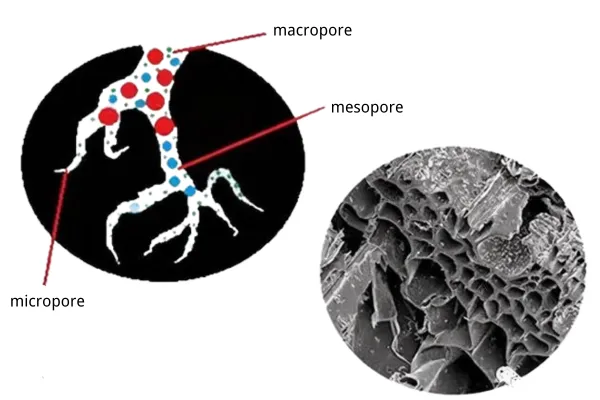

The working principle of activated carbon in solvent recovery primarily involves adsorption utilizing its internal pore structure to adsorb solvent molecules. Activated carbon contains a large number of fine pores, providing a vast surface area that offers numerous adsorption sites.

During the solvent recovery process, exhaust gases containing organic solvent vapors flow into an activated carbon adsorption tower. Due to the large surface area of the pores, solvent molecules can smoothly enter and be adsorbed within them.

Unlike general surface adsorption, solvent molecules can penetrate deep into the pores of activated carbon, significantly increasing the actual adsorption area per unit mass of activated carbon. This achieves the goal of efficiently adsorbing solvents.

Once the activated carbon becomes saturated with adsorbed solvents, methods such as heating can be used to desorb the solvents from the surface of the activated carbon, thereby recovering the solvents.

Process Of Activated Carbon In Solvent Recovery

Adsorption Enrichment

When the solvent concentration in exhaust gas is low, it is first necessary to enrich the solvent concentration through activated carbon adsorption. This step can significantly improve the efficiency of subsequent solvent recovery.

The high specific surface area and developed pore structure of activated carbon endow it with excellent adsorption capacity, effectively capturing and enriching solvent molecules.

Solvent Separation

After adsorption enrichment, solvent molecules are highly concentrated on the surface of the activated carbon. The next step is to desorb and separate the solvents from the activated carbon through methods such as heating. This step achieves efficient separation and recovery of the solvents.

Solvent Recovery

The separated solvents are then subjected to processes such as condensation and filtration to obtain high-purity solvent products, which can be directly reused in the production process.

This not only significantly reduces the cost of purchasing fresh solvents but also reduces the amount of waste generated, achieving solvent recycling.

Advantages Of Activated Carbon For Solvent Recovery

Activated carbon, due to its unique physical and chemical properties, is widely used in the field of solvent recovery. Its advantages include:

- Developed Pore Structure: Activated carbon has a highly developed pore structure, providing a large specific surface area and adsorption capacity, capable of effectively adsorbing organic solvent vapors.

- Adsorption Performance: Activated carbon has strong adsorption capacity for organic solvents, particularly for the recovery of benzene, toluene, xylene, acetone, alcohols, esters, ethers, gasoline, and other organic solvents.

- Strength and Abrasion Resistance: Activated carbon possesses high mechanical strength and abrasion resistance, making it more durable in industrial applications and reducing loss during transportation and use.

Selection Of Activated Carbon For Solvent Recovery

Choosing the right activated carbon for solvent recovery is crucial. Different activated carbons vary in pore size distribution, specific surface area, and adsorption capacity, necessitating selection based on specific solvent types and recovery needs. Extruded activated carbon is commonly used for solvent recovery.

It is refined using high-quality anthracite as raw material, featuring high strength, fast adsorption speed, high adsorption capacity, large specific surface area, and developed pore structure. It is primarily used for recovering benzene, toluene, xylene, ethers, ethanol, gasoline, chloroform, carbon tetrachloride, and other organic solvents.

Its parameters are as follows:

| Parameter | Value |

|---|---|

| Iodine Value (mg/g) | 900-1200 |

| CTC (%) | ≥70 |

| Moisture (%) | ≤5 |

| Ash (%) | 8-12 |

| Strength (%) | ≥93 |

| Density (kg/m³) | 400-550 |

About Tingyuan Carbon

Tingyuan is an enterprise specializing in the research, production, sales, and service of activated carbon. Our extruded activated carbon features a high specific surface area and developed pore structure, giving it strong adsorption capacity and making it highly effective for solvent recovery.

As a professional activated carbon supplier, Tingyuan Carbon is committed to providing high-quality products and professional technical support to our customers. If you need further consultation or wish to learn more about our products, please feel free to contact us.

- Whatsapp: +86-13323528218

- Email: info@tycarbon.com