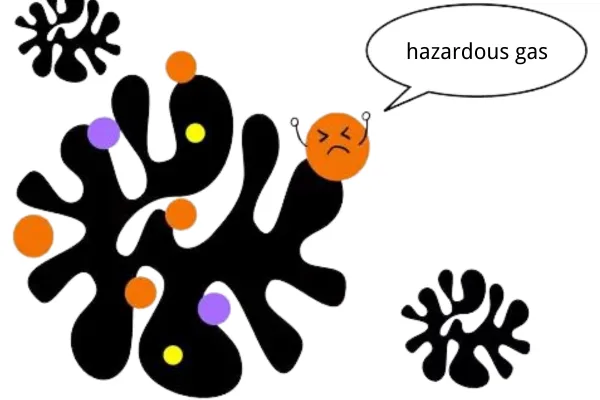

Volatile Organic Compounds (VOCs) are a class of organic chemical substances widely present in industrial emissions and daily life, leading to a decline in air quality and posing a threat to human health.

Activated carbon, as an efficient adsorbent, can effectively remove VOCs due to its porous structure and large surface area, thereby reducing their harm to the environment and human health.

This article will provide you with a detailed introduction to the application of activated carbon in VOC removal, helping you better understand this technology.

What Are Volatile Organic Compounds (VOCs)?

Volatile Organic Compounds (VOCs) are organic compounds that readily evaporate at room temperature. Common VOCs originate from industrial emissions, indoor construction materials, cleaning agents, paints, and vehicle exhaust.

Indoor environments typically have higher VOC concentrations compared to outdoors, which can lead to serious health risks such as respiratory diseases, neurological damage, and increased cancer risks with prolonged exposure.

Working Principle Of Activated Carbon For VOC Removal

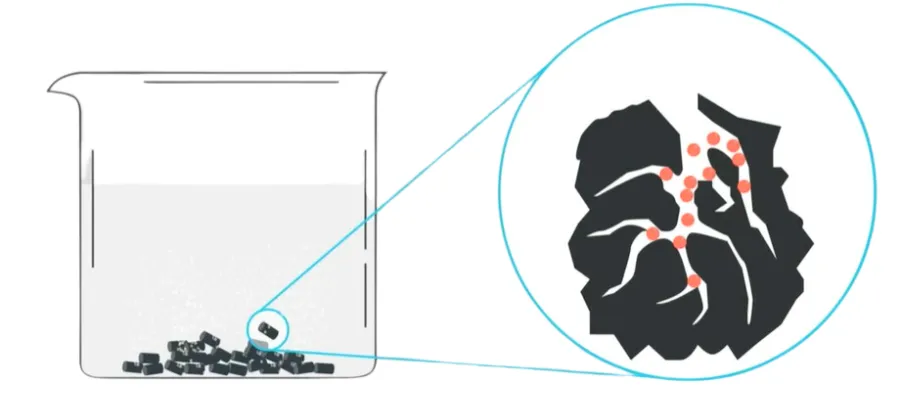

Activated carbon removes VOCs based on its highly developed pore structure and large surface area, which provide strong physical adsorption capabilities.

When VOC-laden gas passes through a bed of activated carbon, the porous structure captures and adsorbs these volatile organic molecules through Van der Waals forces, immobilizing them within its pores, thereby purifying the gas.

As the adsorption process progresses, VOC concentrations gradually decrease until they meet emission standards. Once saturated, activated carbon can be regenerated through methods like thermal or chemical processes to restore its adsorption capacity for reuse.

Key Parameters For Selecting Activated Carbon For VOC Removal

In removing VOCs, the choice of activated carbon is not a simple one, but involves a combination of factors. Here are some key points:

Surface Area

Surface area refers to the total area per unit mass of activated carbon. A higher surface area indicates stronger adsorption capacity. Therefore, products with larger surface areas should be prioritized when selecting activated carbon.

Pore Structure

Activated carbon’s pores are categorized into micropores (<2nm), mesopores (2-50nm), and macropores (>50nm). Effective VOC removal relies on micropores and mesopores, necessitating activated carbon with abundant micro and mesoporous structures.

Adsorption Capacity

Adsorption capacity is a crucial indicator of activated carbon’s effectiveness in removing VOCs, typically measured by iodine number and CTC (Carbon Tetrachloride) activity.

A higher iodine number indicates a more developed micro-porous structure and stronger adsorption capacity. CTC value indicates the ability of activated carbon to adsorb organic compounds.

Mechanical Strength

High mechanical strength ensures activated carbon durability during use, reducing the likelihood of breakage and ensuring stable performance over time, which is critical for applications requiring frequent replacement and handling.

Chemical Modification

Certain types of activated carbon undergo chemical modifications to significantly enhance their adsorption capacity for specific VOCs.

For instance, treatments like acid-base treatments or catalyst loading can improve activated carbon’s effectiveness in adsorbing substances like formaldehyde. Thus, chemically modified activated carbon may be preferred for specific requirements.

Get a competitive quoteSelection Of Activated Carbon For VOC Removal

Choosing the right activated carbon for VOC removal is crucial to ensure effective air purification. Typically, granular and extruded activated carbon are used for air VOC purification.

Granular Activated Carbon

Produced from high-quality bituminous coal, refined through processes such as crushing, screening, and activation, granular activated carbon offers a developed pore structure, high surface area, and excellent mechanical strength, effectively removing VOCs. Specifications include:

| Parameter | Specification |

|---|---|

| Iodine Value | 800-1200 mg/g |

| CTC | ≥60% |

| Size | 4-8 mesh, 4-12 mesh |

| Hardness | ≥95% |

Extruded Activated Carbon

Extruded activated carbon, cylindrical in shape, is manufactured through specific carbonization and activation processes. It is known for its excellent mechanical strength, developed pore structure, and efficient adsorption capacity.

The parameters are as follows:

| Parameter | Specification |

|---|---|

| Iodine Value | 800-1200 mg/g |

| CTC | ≥60% |

| Surface Area | 800-1200 m²/g |

| Ash Content | ≤10% |

| Hardness | ≥95% |

| Size | 4mm |

About Tingyuan Carbon

As a professional supplier of activated carbon, Tingyuan Carbon provides high-quality and reliable products. We possess advanced production equipment and a comprehensive quality control system, ensuring stable and dependable product quality.

Tingyuan Carbon boasts extensive industry experience and a dedicated technical team committed to delivering efficient and environmentally friendly solutions. For further inquiries or to learn more about our products, please feel free to contact us.

Whatsapp: +86-13323528218

Email: info@tycarbon.com