Activated carbon is widely used as an efficient adsorbent for gold recovery, capable of adsorbing gold ions from slurry due to its high surface area and porous structure.

In processes like CIP (Carbon-in-Pulp), CIL (Carbon-in-Leach), and CIC (Carbon-in-Column), the use of activated carbon is crucial for improving gold recovery rates.

This article will detail the application of activated carbon in gold recovery, helping you better understand this technology.

Gold Recovery Process

The gold recovery process mainly involves extracting gold from ore or waste. Typically, water and cyanide (such as calcium cyanide, sodium cyanide, or potassium cyanide) are mixed with the ore or waste to form a slurry.

The gold dissolves and forms a gold cyanide solution. Activated carbon is then used to separate and store the gold from the solution.

Modern gold recovery mainly uses three basic operational systems:

Carbon-in-Pulp (CIP)

CIP is a method where activated carbon is directly added to the gold-containing slurry. The activated carbon adsorbs the gold dissolved in the cyanide solution, forming “loaded carbon.”

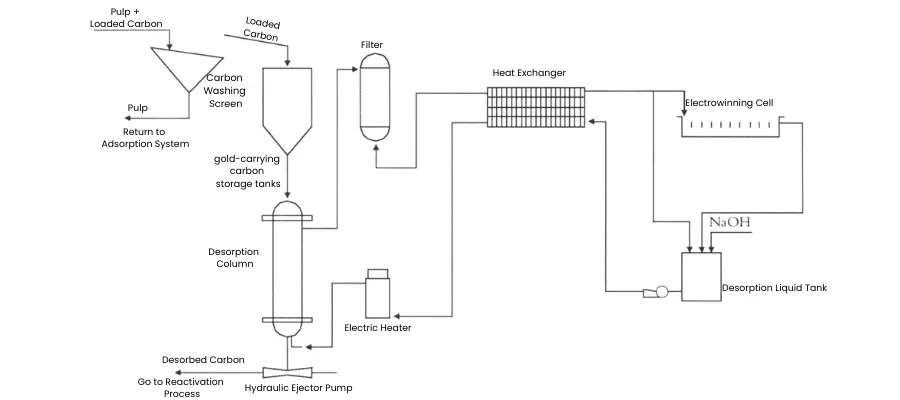

The loaded carbon is then treated through an elution process (using a cyanide solution containing sodium hydroxide) to release the adsorbed gold.

Carbon-in-Leach (CIL)

The CIL process involves adding activated carbon to the cyanide leaching process, simultaneously carrying out leaching and adsorption.

This method combines the leaching and adsorption steps into one, reducing gold retention time and loss during production.

CIL is suitable for processing low-sulfur, low-mud content oxidized gold ores and can significantly save on construction and operating costs.

Carbon-in-Column (CIC)

The CIC method involves treating the cyanide-leached solution by passing it through columns filled with activated carbon.

Gold is adsorbed onto the activated carbon from the solution and then recovered through an elution process.

CIC is typically used for processing lower-grade gold ores or as a supplement to other processes to enhance gold recovery rates.

All three processes rely heavily on activated carbon, and the performance of the activated carbon directly affects the efficiency and economics of the entire gold recovery process.

So, what key indicators should be considered when selecting activated carbon for gold recovery? Please read on to find the answer.

Key Indicators Of Activated Carbon For Gold Recovery

In the field of gold recovery, selecting the right activated carbon is not a simple task but involves a comprehensive consideration of various factors.

Different types of activated carbon have distinct material characteristics and must be selected specifically for the application scenario to maximize their advantages in the gold recovery process.

The key indicators of activated carbon for gold recovery mainly include the following aspects:

Adsorption Capacity (K Value)

The K value is an indicator used to measure the equilibrium adsorption characteristics of activated carbon during adsorption. The pore structure and surface chemical properties of activated carbon determine its adsorption capacity for gold ions.

Specifically, the higher the K value, the more gold cyanide complex the activated carbon can adsorb at equilibrium.

Adsorption Rate (R Value)

In the gold recovery process, the R value reflects the speed and efficiency of activated carbon in adsorbing gold cyanide complexes.

Specifically, the higher the R value, the stronger the ability of activated carbon to adsorb gold cyanide in a short time, and the better the kinetic performance of the adsorption process.

Mechanical Strength and Hardness

The mechanical strength or hardness of activated carbon is crucial in the gold recovery process. High hardness activated carbon is less likely to break during handling and transport, reducing carbon loss and subsequent gold loss, while maintaining the integrity of its particle form, thus maintaining its adsorption performance.

Particle Size Distribution

Considering the particle size distribution of activated carbon is crucial in the gold recovery process as it directly impacts adsorption efficiency.

In gold recovery, 6-12, 8-16 mesh coconut shell activated carbon is commonly used, which helps to increase the rate of adsorption and recovery of gold, and reduces the stress and loss of gold in the operation.

Carbon Tetrachloride Activity (CTC)

CTC is a key indicator of the adsorption capacity of activated carbon. Higher CTC means stronger adsorption performance. The CTC of activated carbon for gold recovery is typically 50-60%.

Iodine Number

The higher the iodine number of activated carbon, the more developed its porosity. Under certain operating conditions, the gold loading capacity and adsorption rate of activated carbon are higher.

Get a competitive quoteSelecting Activated Carbon For Gold Recovery

For gold recovery, coconut shell activated carbon is typically used. Our activated carbon is made from selected high-quality coconut shells to achieve hardness and abrasion resistance.

The highly developed microporous structure is particularly suitable for providing optimal adsorption in cyanide solutions in CIP, CIL, and CIC systems.

Our specialized activated carbon for gold recovery offers the following advantages:

- Higher gold adsorption capacity for maximum gold loading

- Excellent gold adsorption rate for high throughput

- Outstanding hardness to minimize gold loss and prevent screen blockage

- Ability to release gold faster and more effectively

Relevant Products:

6-12 Mesh Coconut Shell Granular Activated Carbon For Gold Recovery

About Tingyuan Carbon

Tingyuan Activated Carbon Company are known for supplying high-quality activated carbon, and we own a modern production facility. This allows us to strictly control product quality at every stage, from raw material procurement to production.

As a supplier of activated carbon, we have always been committed to innovation, continuously improving product quality to meet the diverse needs of customers in different regions.

Additionally, our company has three master-level consultants in activated carbon production, whose expertise and extensive experience provide reliable support for our technological innovation and product quality.

If you are seeking a quotation or technical support, please feel free to contact us. We will do our best to provide you with satisfactory service.

Whatsapp: +86-13323528218

Email: info@tycarbon.com