Syrup, widely used in food, beverage, and chemical industries, is an important raw material whose quality and purity directly affect the final product’s quality.

However, during the production and processing of syrup, impurities such as pigments and odors may be present, affecting its appearance and flavor. Therefore, effectively removing these undesirable substances to improve the purity and quality of syrup has become a key issue in the sugar industry.

Activated carbon, as a versatile adsorbent, can effectively remove these unnecessary components, ensuring the purity and safety of the syrup.

In this article, we will delve into the application of activated carbon in syrup decolorization. Through this article, you will learn the important role of activated carbon in syrup decolorization and how to choose the right activated carbon products to achieve efficient purification.

Color Impurities in Syrup and the Need for Removal

During the production process, syrups may contain various impurities including pigments, organic compounds, inorganic substances, proteins, and ash. These impurities can affect the appearance, taste, and stability of the syrup, and may even lead to spoilage or failure to meet food safety standards.

Therefore, efficient decolorization of syrup to remove these undesirable components is a critical technology in the sugar industry. Activated carbon decolorization not only enhances the appearance quality of the product but also improves its taste and aroma.

Now that we know there are many impurities in syrup that need to be removed, let’s continue reading to understand the adsorption principle of using activated carbon to decolorize syrup.

Principle of Activated Carbon in Syrup Decolorization

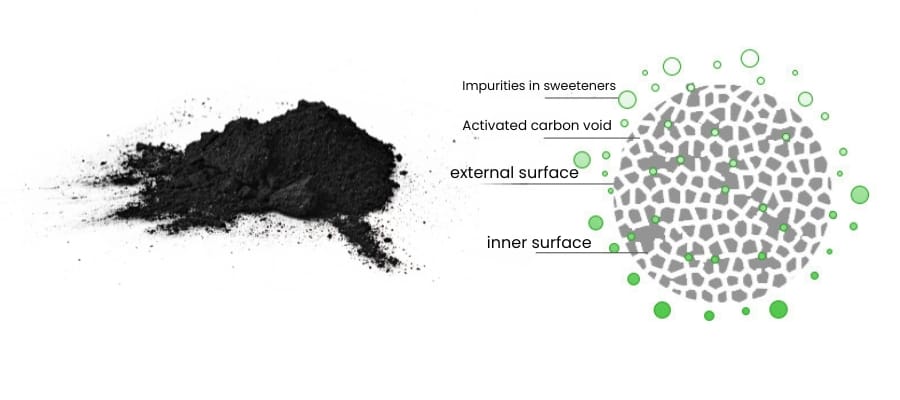

As an excellent adsorbent material, activated carbon, with its unique pore structure and surface chemical properties, can efficiently remove colored impurities from syrupr, restoring the product’s original color and improving its quality.

Activated carbon decolorization of syrup is mainly based on two mechanisms: physical adsorption and chemical adsorption:

- Physical Adsorption: Activated carbon has a developed pore structure and large specific surface area, which can adsorb colored impurities onto its surface through physical forces such as van der Waals forces and capillary forces, achieving decolorization.

- Chemical Adsorption: The surface of activated carbon contains functional groups that can chemically react with certain colored impurities, fixing them onto the activated carbon surface and achieving irreversible adsorption.

Advantages of Activated Carbon in Syrup Decolorization

Activated carbon, as a high-efficiency adsorbent material, exhibits significant advantages in the process of syrup decolorization due to its unique characteristics and multifunctionality. Here are the main advantages of activated carbon syrup decolorization:

High Adsorption Capacity

Activated carbon has an extremely high specific surface area and developed pore structure, providing numerous adsorption sites. This allows activated carbon to quickly and efficiently adsorb color molecules and impurities in syrup, improving decolorization efficiency and ensuring the purity of syrup.

Chemical Stability

Activated carbon demonstrates excellent chemical stability under various production process conditions. It can work stably across different temperature and PH ranges without reacting adversely with syrup, ensuring the safety and stability of the decolorization process.

How to Choose Activated Carbon for Syrup Decolorization?

For syrup decolorization, the commonly used activated carbon is food-grade powder activated carbon. This type of activated carbon has a highly developed pore structure, capable of rapid diffusion and efficient adsorption of small organic molecules.

It also possesses good hydrophobicity and rapid decolorization efficiency, making it very suitable for the decolorization treatment of food-grade syrup.

Below are some parameters of this type of activated carbon:

| Characteristics | Wood-Based Powdered Activated Carbon |

|---|---|

| Iodine Value | 900-1000 mg/g |

| Molasses Value | 200-300mg |

| Particle Size | 100 / 200 / 325 mesh |

| PH Value | 3-5 |

Ready to Purchase?

Activated carbon plays an irreplaceable role in ensuring the quality and safety of syrup. Choosing the right activated carbon products can not only enhance the quality of syrup but also ensure the safety and environmental friendliness of the production process.

As a professional activated carbon supplier, Tingyuan Activated Carbon Company is committed to providing high-quality products and professional technical support to our customers. If you need further consultation or wish to learn more about our products, please contact us.

Whatsapp: +86-13323528218

Email: info@tycarbon.com