Beer is one of the most popular beverages among contemporary people, with a very broad audience. However, during the brewing process, beer can develop certain pigments and impurities, such as those from malt, phenolic compounds, and more.

These substances not only affect the appearance of the beer but can also impact its taste and flavor.Therefore, decolorization of beer is necessary. Activated carbon, with its strong adsorption capabilities, can effectively adsorb pigments and odor substances in beer, thereby enhancing the quality of the beer.

This article will explore the importance of beer decolorization, the application principles of activated carbon in beer decolorization, its advantages, practical methods of operation, and how to select the appropriate activated carbon.

Importance of Beer Decolorization

Beer decolorization can significantly improve the appearance of beer, making its color clearer and more transparent, which attracts consumers.

It also removes impurities and off-flavors that affect taste, enhancing the overall flavor of the beer to meet consumers’ expectations for high-quality beer.

Moreover, the decolorization process helps maintain consistency across different batches of beer, which is crucial for maintaining brand image and market competitiveness.

Next, Let’s understand the principle of activated carbon beer decolorization.

Adsorption Principle of Activated Carbon

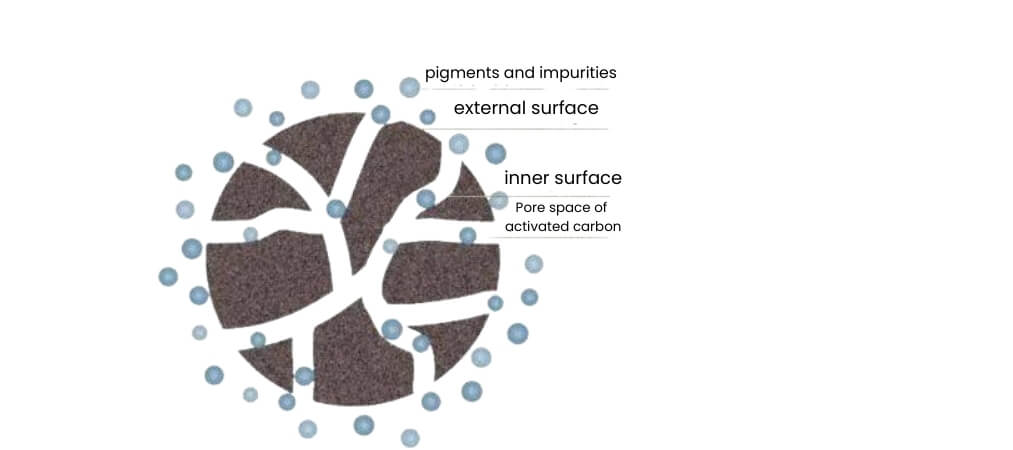

Activated carbon is a highly porous material with a large specific surface area, containing numerous micropores and mesopores.

These pores give activated carbon an extremely strong adsorption capacity, allowing it to effectively adsorb pigments, impurities, and odor molecules from liquids.

During the beer decolorization process, activated carbon utilizes its surface area and pore structure to engage in physical adsorption with pigment molecules in the beer, thereby removing unwanted colors and impurities, enhancing the beer’s clarity and taste.

Why do most people choose activated carbon for decolorization? Please continue reading to find out.

Advantages of Activated Carbon in Beer Decolorization

Activated carbon is widely used for various purposes, including beer decolorization and impurity removal. It is an efficient, economical, and environmentally friendly method that removes pigments and odor substances from beer through physical adsorption, thereby improving the beer’s appearance, enhancing its taste, and extending its shelf life. The Strengths include:

- Strong Adsorption Performance: Powdered activated carbon has a high surface area and large adsorption pores, providing excellent decolorization effects and high loading capacity. It can quickly remove pigments and impurities from beer.

- Fast Filtration Speed: A fast filtration speed means that the contact time between the beer and activated carbon can be shortened, which helps to quickly adsorb pigments and other impurities from the beer, thereby speeding up the decolorization process.

Practical Methods for Decolorizing with Activated Carbon

Activated carbon is the most commonly used material for beer decolorization. It is not only economical and practical but also very simple to operate. Emphasizing the decolorization process with activated carbon is crucial to ensure the uniform color and pure taste of beer. Below, I will introduce how to use activated carbon for decolorization:

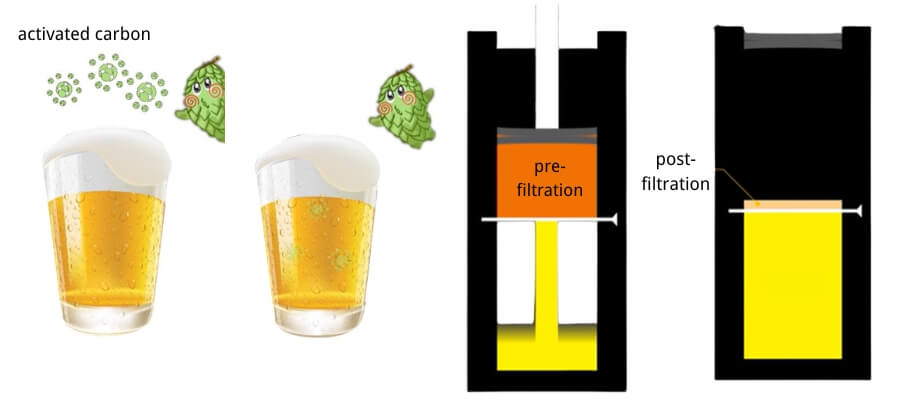

- Determining the Amount to Add: Based on the initial color of the beer and the desired decolorization effect, determine the appropriate amount of activated carbon to add. Typically, adding 0.1-0.5 grams of activated carbon per liter of beer achieves good decolorization results.

- Adding Process: Evenly add the activated carbon to the beer and stir well to ensure thorough contact between the activated carbon and the beer. The stirring time is usually between 30 minutes to 1 hour, depending on the actual situation.

- Filtration: After stirring, use an appropriate filtration device to filter out the activated carbon and the adsorbed impurities, resulting in clear and transparent beer.

- Quality Testing: Conduct necessary quality tests on the filtered beer, including color, transparency, taste, and microbiological indicators, to ensure the product meets quality standards and consumer expectations.

How to Choose the Right Activated Carbon

Now that we have a detailed understanding of the process of decolorizing beer with activated carbon, are you wondering what kind of activated carbon to choose? Please read on.

Selecting the right activated carbon for beer decolorization is crucial as it enhances the color and taste of the beer and ensures food safety. The most commonly used activated carbon is currently wood-based powder activated carbon.

The following are some parameters of wood-based powdered activated carbon specialized for beer decolorization:

- Iodine Value: 700-1000 mg/g

- Molasses Value: 200-230 mg

- Size: 100 / 200 / 325 mesh

This type of activated carbon has a strong adsorption capacity, typically adsorbing 10%-15% of its own weight. Adding 1% activated carbon to the beer can completely remove the color from light beer.

Currently, our specialized beer decolorization carbon is exported to various countries such as Turkey, Malaysia, Spain, and France. Additionally, our company holds certifications such as NSF, KOSHER, and HALAL, ensuring the quality of our products.

Get a competitive quoteReady to Purchase?

Choosing the right activated carbon is crucial for beer decolorization. If you need a product quote or technical support, please contact us. Need to get in touch quickly? Click the email or phone number below.

- Email: info@tycarbon.com

- Phone:+86-13323528218